ColdTABLE

专为光学实验设计的超低温平台

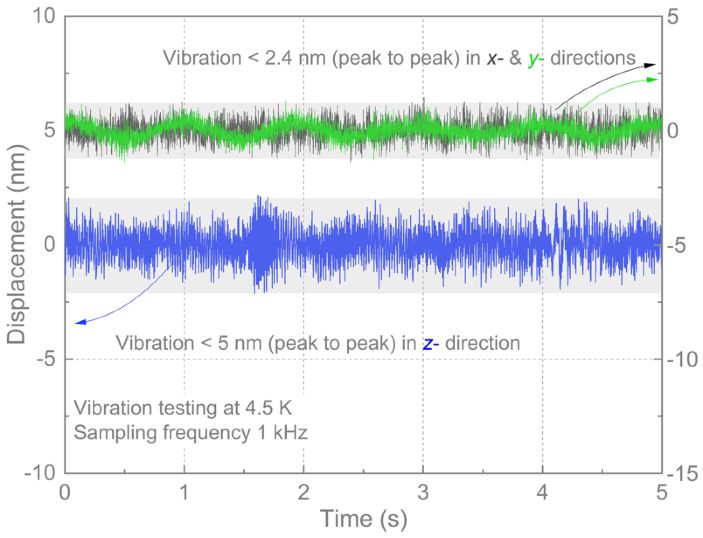

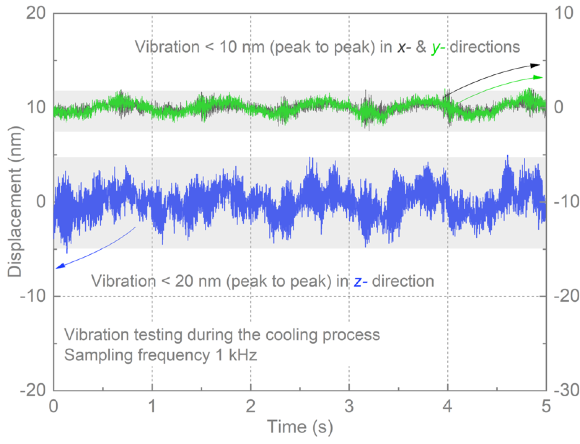

1. 振动情况

– < 5 nm 振动水平 @ 3个方向

2. 降温性能

– 4.2 K 系统最低温

– 180 分钟,系统可从300 K降至 5 K

3. 尺寸信息 & 光学接口

– 超大样品腔尺寸可提供 > ∅ 100 mm 4K区域

– 丰富的光学窗口: 侧面8个光学窗口 + 顶部1个光学窗口

4. 低温物镜&压电运动模组 (选件)

– 低温物镜: N.A. 0.90, 0.60 & 0.36

– 完整的压电运动解决方案

·产品性能

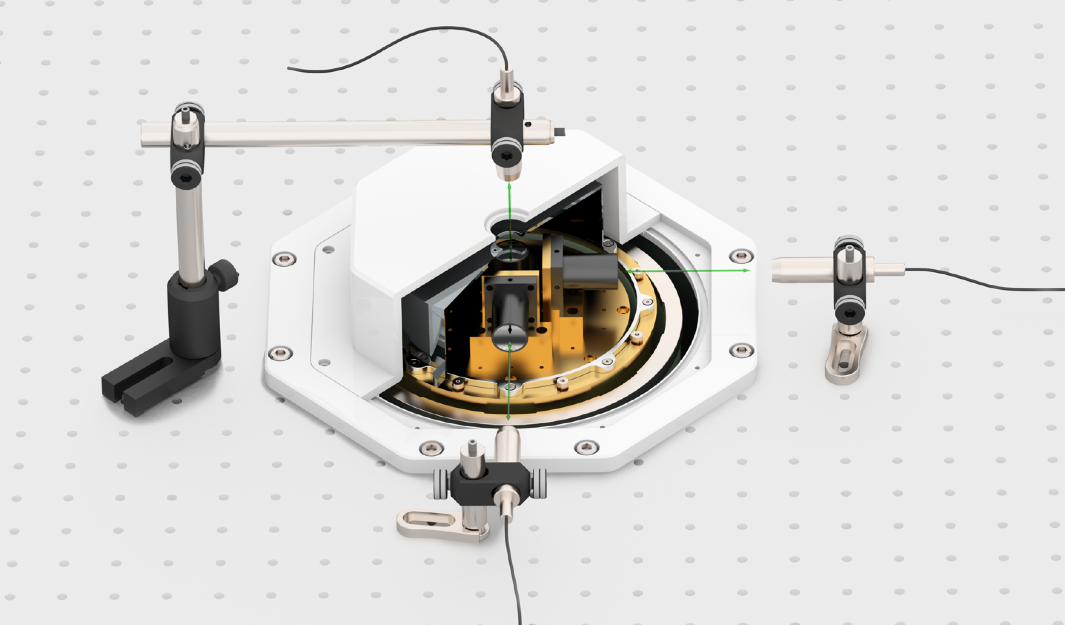

产品性能 1 — 振动测试:结果 & 方法

振动水平是闭循环光学低温恒温器的最为关键的指标:ColdTABLE将振动控制在了纳米量级

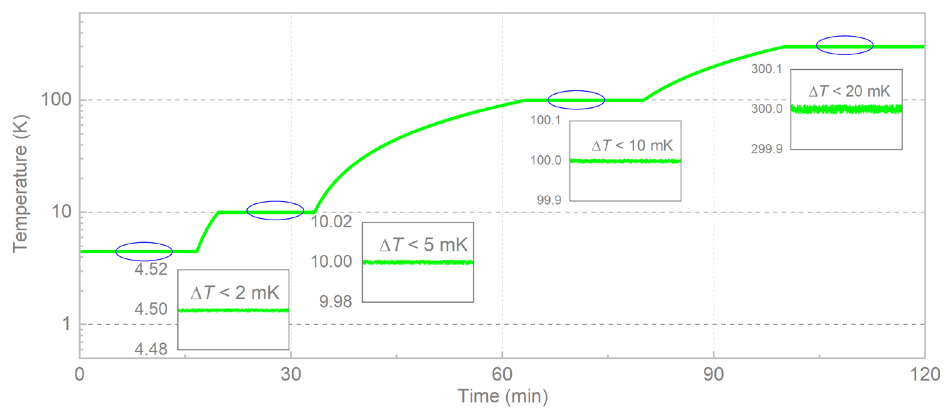

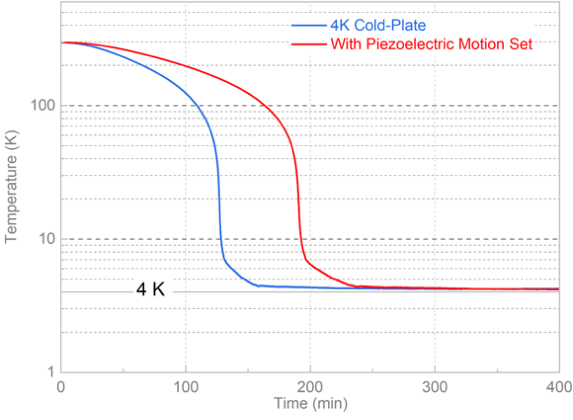

产品性能 2 — 降温时间 & 温度稳定性

基于精巧的低温结构设计和极可靠的“Kevinion”系列低温温控仪,ColdTABLE展现了极致的温度稳定性。

➡ ColdTABLE 系统的温度控制模块

为用户提供极可靠和稳定的低温环境

低温温度控制模块构成

– 低温温度计, Cernox 1050

– 低温加热器, 50 Ω, max. 50 W

2. 低温温度模块位置

– 系统的默认温度控制模块(包括温度计和加热器)直接安装在4K样品板的底面

3. 低温温度控制器

– 来自多场科技的“Kelvinion”温度控制器

4. 可升级选件

– 如果客户需要,ColdTABLE最多支持安装4支低温温度计

5. 温控电学接口

– 所有电学接口转接放置在4K冷环区域

·样品腔

➡ 标准光学接口布局

➡ 真空腔 (上半部分)

8个光学窗口均匀分布在样品腔侧面;

1个顶部光学窗口;

光学窗口外侧支持30 mm光学笼式结构&SM1 螺纹 / SM1.5 螺纹。

➡ 50K 防辐射屏蔽罩

镜面抛光的纯铝材质,极高的反射系数及极小的质量。

➡ 真空腔 (下半部分)

光纤气密接口;

其他功能气密接口。

图1. ColdTABLE 样品腔图示

➡ 样品腔温度分布区域划分

图 2. 无真空罩和防辐射罩的样品腔俯视图

(1) 50K 环状区域

用于低温下的热沉及防辐射罩的固定

(2) 4K 冷盘

整个区域皆可达到系统的最低温,其包含了4K 环状区域和样品区域,详见下图

(2.1) 4K 环状区域

(隶属4K冷盘)

所有的低温电学接口皆放在此处,确保各种引线可以被充分冷却,不会抬升样品温度

(2.2) 4K 样品区域

(隶属4K冷盘)

样品所在的位置,该部分完全预留给最终用户

样品腔 1 — 光学接口布局

作为一款专为光学实验而设计的低温系统,我们为ColdTABLE预留了丰富的光学接口。如适用于自由空间激光的光学窗口:侧面的8个窗口和顶部1个光学窗口;和适用于光纤的多种真空气密接口。

➡ 标准光学接口配置

8个侧面光学窗口,均匀分布在样品腔四周;

1个顶部光学窗口;

光学窗口外表面皆可支持30mm光学笼式接口&SM1或SM1.5安装螺纹

样品腔的光学接口:光学窗口空间布局

样品腔的剖面图

➡ 真空光学窗口支持光学笼式结构 & SM1.0 / SM1.5 螺纹

∅1 英寸光学窗口,支持30 mm的光学笼式结构

∅1.5 英寸光学窗口, 支持30 mm的光学笼式结构

➡ 真空光学窗口工程草图

光学窗口位置高度信息

光学窗口的详细结构

*提供多种光学镜片可选择

样品腔 2 — 4K 冷盘尺寸信息

为适应客户实际需求,我们提供了两种尺寸的样品腔供用户选择。其中较小的样品腔具有更低的振动水平和更优异的低温性能;而较大的样品腔则为复杂实验提供更充足的实验空间。

Standard

∅100 mm 冷盘

4.5 K 最低温度

5 nm 振动水平

.Max

∅200 mm 冷盘

5.6 K 最低温度

10 nm 振动水平

– 尺寸信息 (mm)

50K 环状区域,I.D. ∅120/O.D. ∅170

4K 冷盘,∅100

4K 样品区域,∅75

50K 环状区域,I.D. ∅210/O.D. ∅280

4K 冷盘,∅200

4K 样品区域,∅148

– 信号接口模块区域 (默认)

24 Pins 用于直流测试

24 pins 用于压电运动控制

1 pcs A-type 模块 (预留)

3 pcs B-type 模块 (预留)

24 Pins 用于直流测试

24 pins 用于压电运动控制

2 pcs A-type 模块 (预留)

3 pcs B-type 模块 (预留)

– 温度计 & 加热器

1 Cernox + 50 W 加热器

1 Cernox + 50 W 加热器

– 其他

样品腔 3 — 4K 冷环区域的电学接口 & 功能配件

多场科技为ColdTABLE提供了多种电学接口选项:默认配置的直流电学线路主要用于温度、压电运动控制,除此之外,ColdTBALE 还预留了射频、低频同轴以及直流等电学接口。

➡ 4K冷环区域电学接口布局 (功能区)

1. ColdTABLE 为电学接口提供了两种通用尺寸的安装转接板

2. 未使用区域可使用空白的安装转接板代替,以便后续使用过程中的升级

3. 在4K环形区域预留安装位置,见右图 (用空白板覆盖)

Standard

.Max

➡ 电学接口 & 功能配件 安装转板接板清单

❖ “A – Type” 电学接口安装转接板

RF 模块 – 类型 (A-Type)

PN:AB1203

– 4 X 2.92mm 接口用于高频测试 (40 GHz)

❖ “B – Type” 电学接口安装转接板

PN:AB1204

▉ DC 模块 (B-Type) — 24 路线路

– 6组 2 mm间距插针组

– 1 x 4规格 2 mm插针组

PN:AB1205

▉ 温度模块 (B-Type)

可用于两路温度控制 & 1路温度监测

– 1 x 6 规格插针组用于温度控制,2 组

– 1 x 4 规格插针组用于温度监测, 1 组

PN:AB1206

▉ 压电运动模块 (B-Type)

可用于驱动三组压电位移台和2组压电扫描台

– 1 x 5规格插针组用于压电位移台,3 组

– 1 x 2规格插针组用于压电扫描台,2 组

PN:AB1207

▉ COAX 模块 (B-Type)

4 SMP 接口用于低噪音电学测试

-3.5 dB @ 1 GHz

❖ 功能配件

碳吸附泵

用于残余气体吸附,确保样品腔的真空

光纤固定夹具

最多可固定4根低温光纤

·选件

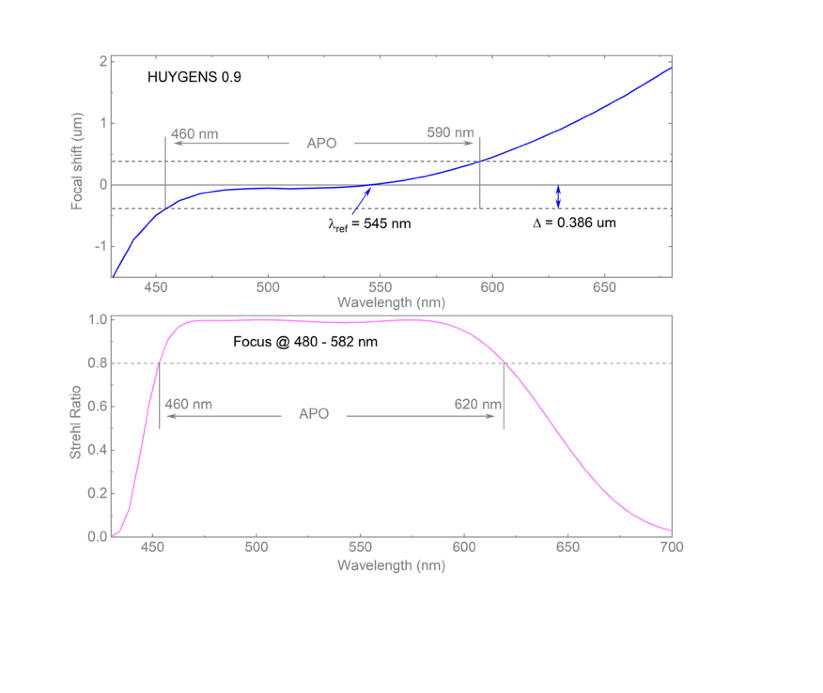

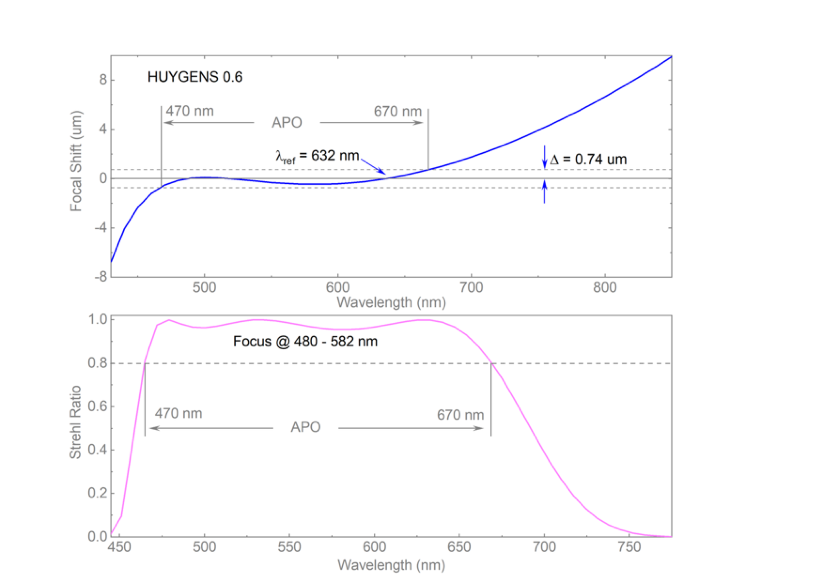

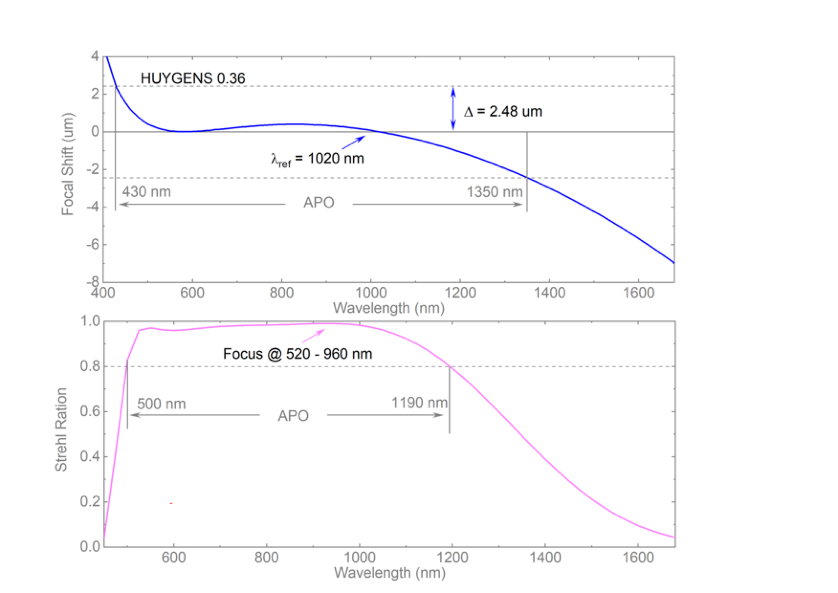

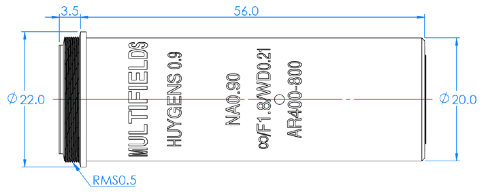

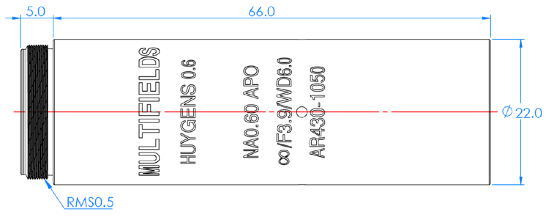

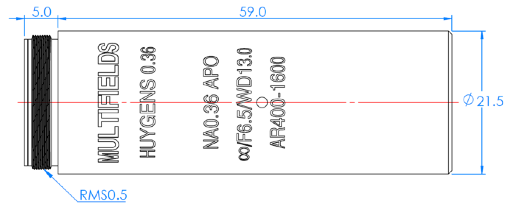

选件 1.1 — 低温物镜, “ Huygens” 系列, 性能指标

多种可在低温长期稳定工作的物件供用户选择

|  |  | ||

名称型号 ➠ | Huygens-0.9 | Huygens-0.6 | Huygens-0.36 | |

1 | 数值孔径 (NA) | 0.90 | 0.60 | 0.36 |

2 | 工作距离 | 1.0 mm | 6.0 mm | 13.0 mm |

3 | AR 镀层 | 430 - 800 nm | 430 - 1050 nm | 400 - 1600 nm |

4 | 消色差范围* | 460 - 590 nm | 470 - 670 nm | 430 - 1350 nm |

5 | 适用环境 | 4 -350 K, non-magnetic structure and high vacuum compatible (ultra-high vacuum on request) | ||

6 | 光圈直径 | Φ 4.30 mm | Φ 4.64 mm | Φ 4.64 mm |

7 | 焦距 | 2.67 mm | 3.87 mm | 6.47 mm |

8 | 质量 | 50 g | 72 g | 55 g |

9 | 直径 | 20 mm | 22 mm | 21.5 mm |

10 | 长度 | 59.5 mm | 71 mm | 64 mm |

11 | 螺纹 | RMS0.5 | ||

*df, chromatic focal shift, Δ = n*λref / (2*NA^2)

选件 1.2 — 低温物镜, “ Huygens” 系列, 数据结果

“Huygens”系列物镜专门为低温强磁场工作环境而设计,并具有尽可能宽的复消色差波长范围。数值孔径包括了0.36、0.60和0.90,相应的工作距离为1.0 mm,6.0 mm和13.0 mm,从而满足不同的研究需求。

通过使用高数值孔径N.A.~ 0.90的低温物镜,用户可以提高实验空间分辨率和光子收集效率;另一方面,超长工作距离的低温物镜可满足高压金刚石砧(DAC)的实验需求,实现GPa高压下的拉曼和荧光测试。

➡ “Huygens”系列 — 焦移 & Strehl比率仿真结果

焦移: 不同波长下焦面相对参考波长λref. 焦面的移动距离 Δ = n*λref / (2*N.A.^2): 景深.

Strehl Ratio: 相对理想透镜,不同波长下峰值强度。

选件 2.1 — 压电运行模组, 产品系列

多场科技可提供完整的低温压电运动解决方案,涵盖所有运动模块,如具有长行程范围的线性、旋转和倾斜的位移台,以及满足高分辨率和小范围动态运动需求的扫描台。

压电运动模块是多场科技的一个独立产品线,更多详细信息见低温压电运动。

选件 2.2 — 压电运动模组. II, 推荐选型

适用于ColdTABLE压电运动模组的推荐组合。

➡ 默认型号

标准低温压电运动解决方案,6mm x 6mm x 6mm运动范围,带闭环控制。

➡ 长行程型号

长行程低温压电运动解决方案,XY平面 20mm x 20mm行程,Z方向6mm行程。

➡ 大负载型号

用户可使用该组合来进行高压实验,因为金刚石对顶砧自身非常重。

➡ 柔性导热连接

为了结构刚性和减轻重量,我们选择了钛来替代高导热铜作为运动模块的主框架。因此,在真空环境中,我们无法将4K冷板的温度有效地传递给样品。为解决该问题,我们使用高导热的无氧铜柔性导热部件,以确保样品运动不会受到影响,同时可以将样品温度与系统冷板温度尽可能保持一致。

·详细参数

将低温低振动技术与纳米运动、低温物镜及其他技术相结合,为低温光学实验提供全面的解决方案。

ColdTABLE 系统, 详细参数

一般指标 | ||

1 | 冷却方式 | 闭循环GM 制冷机 |

2 | 减震技术 | 被动减震:气浮隔振 & 多种阻尼减震 |

3 | 样品环境 | 真空环境 |

4 | 最低温区域 | Dia 100 mm & Dia 200 mm |

5 | 样品安装区域 | M3 螺孔, 10 mm x 10 mm 矩阵分布 |

6 | 加热器 & 低温温度计 | 1支温度计+ 1 支加热器,用于系统温度控制和监测 |

7 | 光学窗口 | 1 个顶部窗口 + 8 个侧面窗口 |

8 | 控制操作界面 | 自动化控制软件,提供LabVIEW & Python 驱动程序 |

核心指标 | ||

9 | 温度范围 | 4.5 K - 350 K |

10 | 降温时间 | < 180 mins |

11 | 温度稳定性 | 2 mK @ 4.5 K, 20 mK @ 300 K |

12 | 制冷功率 | 30 mW @ 5.0 K |

13 | 振动幅度 | < 5 nm pk-pk @ 3-axis, 最低温 |

14 | 极限真空 | 1E-8 mBar |

电学 & 光学接口 | ||

15 | 电学接口 | 24DC 线路,预留给用户 + 24DC 线路,用于压电运动控制 |

16 | 射频接口 | 4 x 2.92 mm气密接头,最高可达 40 GHz |

17 | 光纤接口 | 4 个单模光纤的气密接头 |

18 | 预留低温转接板数量 | 2 pcs |

选件 | ||

19 | 低温运动模组 | 25 mm & 35 mm 系列低温压电位移台和扫描台 |

20 | 低温物镜 | N.A. ~0.36, 0.6 & 0.9 低温无磁物镜 |

闭循环制冷机 | ||

21 | 耗电功率 | 1.5 kW @ 220 V |

22 | 冷却方式 | 风冷 |

系统尺寸 & 质量 | ||

23 | 外型尺寸 (W x L x H) | 800 mm x 1000 mm x 800 mm @ 光学平台 |

24 | 系统质量 | 150 kg @ 光学平台 |

可选升级 | ||

25 | 显微镜 | 共聚焦显微镜 |

·系统组件

气浮隔离系统

光学平台